Environmental test chambers such as temperature chambers are used by manufacturers to check the stability and lifespan of a product during its developing stages to ensure the best quality product once it reaches the general market. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Searching for temperature chambers? Hastest Solutions has multiple configurations which may be just what you are looking for. Our table top temperature chamber has a temperature range of -40°F to +284°F, while our medium size chamber has a temperature range of -40°F to +302°F. Our engineers will also work with you to design a temperature chamber to meet your company’s needs. Our units use...

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Temperature Chamber Manufacturers

Industries such as medical, consumer, construction, food processing, and automotive use temperature testing on their products, revealing potential flaws and malfunctions. Temperature chambers can produce an environment with temperatures from below freezing to as high as 350F.

The goal of test chambers is to accurately predict, and then allow the manufacturer to correct if needed, the response of a product to the environment. Therefore, it is important that the chamber produces an environment as close to that of nature as possible.

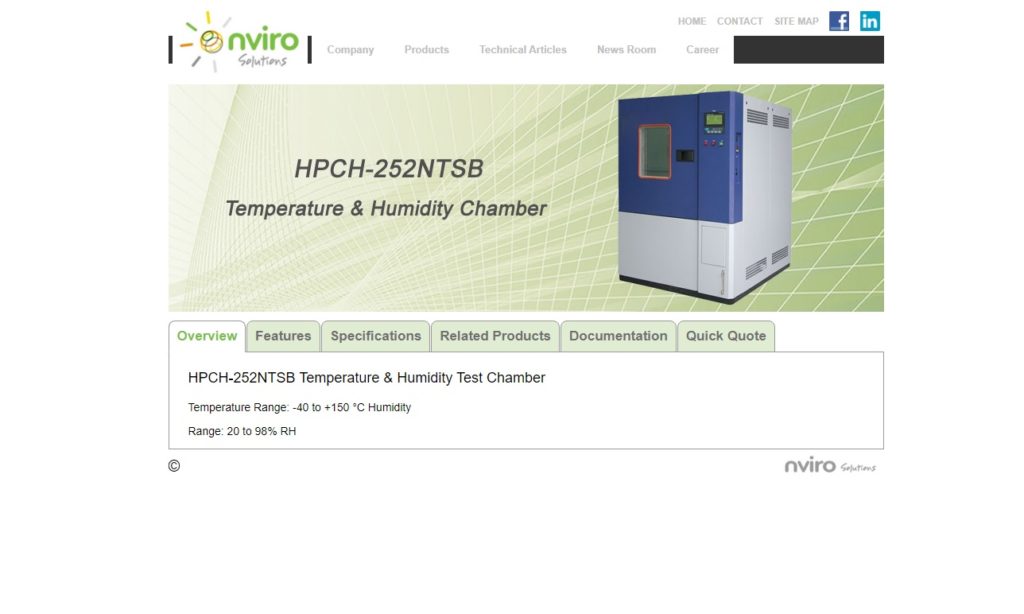

As existing temperature is closely linked with relative humidity, chambers that combine the effects of temperature and humidity are common. Temperature chambers can also be used as storage spaces for materials that are sensitive to adjustments in temperature, especially in the medical and pharmaceutical industries.

The range of products that require temperature testing is broad; therefore, temperature chambers are available in many sizes, including compact benchtop chambers and much larger walk-in chambers designed according to the manufacturer needs. Many chambers are custom designed based not only on the size and shape of the product being tested but also on its intended use. The validity of the test results is important for future manufacturing changes and improvements, and therefore, chamber construction should be carefully considered.

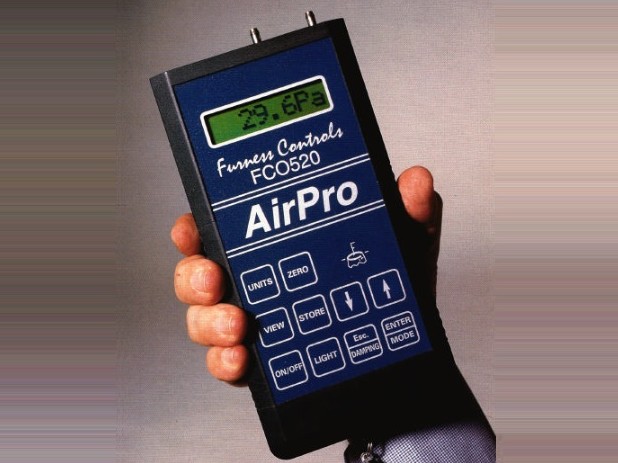

Temperature controls and precision are an important element of undergoing the tests and recording the results for future reference. This is usually done by electronic sensors in order to achieve the most accurate reading. Another consideration in temperature chambers is the method of distribution of air to achieve a uniform temperature pattern within the sealed chamber. Each element of the test and testing conditions has to be taken into consideration - existing environment and climate, the potential addition of interior chamber lighting and thus extra heat, and the variations that already exist between products and materials being tested.

Depending on the industry doing the testing, standards for execution of the process and recording will differ, and yet an improved product is a typical result. It may be an expensive and time-consuming procedure depending on the size and process undertaken, and yet it is a wise manufacturing choice to undergo temperature testing, especially in terms of long-term expenditure and future benefit.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services