An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly. These highly technical pieces of equipment are capable of simulating the types of conditions a product may face while in use. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

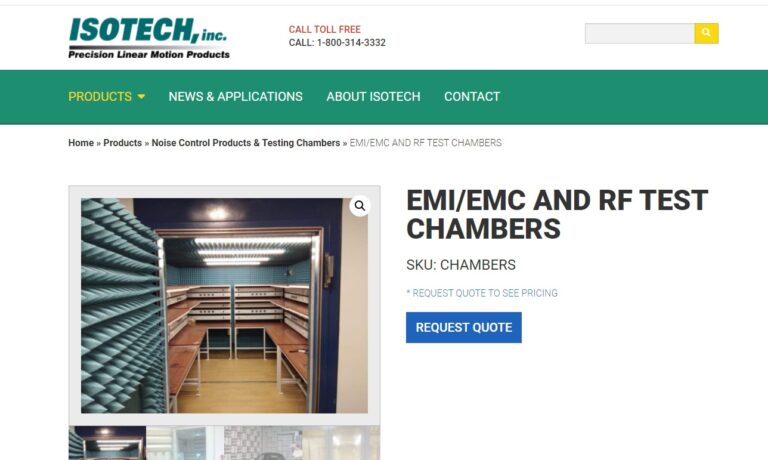

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Environmental Test Chamber Manufacturers

Environmental Chambers

- What is an Environmental Chamber?

- Different Types of Environmental Chambers

- Uses for an Environmental Chamber

- Industries that Use Environmental Chambers

- The Types of Testing Completed in an Environmental Chamber

- And much more…

Chapter One – What is an Environmental Chamber?

An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly. These highly technical pieces of equipment are capable of simulating the types of conditions a product may face while in use. The conditions in the chamber are controlled by a series of computer monitors that can rapidly change the conditions or slow them down to last for long periods of time.

The stipulations and requirements for testing are predetermined to offer the most accurate data concerning a product’s performance in the types of conditions it would confront during its use. In most cases, the parameters for testing exceed the normal conditions of product use.

Environmental chambers provide manufacturers with valuable data for the improvement of their products and guidance in how to adjust products that are presently on the market. These technologically advanced instruments help industries produce products of higher quality and longevity.

Chapter Two – Different Types of Environmental Chambers

Environmental chambers come in a wide variety of sizes and designs in order to meet the changing demands of industry. In most cases, environmental chambers are designed to perform several tests in one cycle, which can be programmed to be completed individually or combined to occur all at once.

The two most important types of tests are those regarding temperature and humidity, which are the top two reasons for product failure. Environmental chambers have the ability to create any type of weather conditions from freezing cold to tropical heat as well as harsh conditions and hazards.

Types of Environmental Chambers

Temperature Chambers

Temperature is the number one reason that products fail. The types of tests that are performed in temperature test chambers are referred to as thermostatic tests. To test the resilience of a product against temperature variations, temperature chambers are capable of producing temperatures that vary between -70° C up to temperatures in excess of 180° C.

The types of tests in a temperature chamber may expose a product to the same gradient for days or weeks. Other tests rapidly cycle through temperatures to examine a product’s reaction to the variations.

Humidity Chambers

Humidity is the second most damaging factor to cause product failure, which is produced by the combination of moisture in the presence of increased temperature. In most cases, humidity test chambers partner with temperature chambers since heat is a requirement for producing humid conditions.

As is true of temperature test chambers, humidity test chambers are capable of producing several climatic conditions. Tests can be performed in a static state without any variation in conditions or a dynamic state where conditions change either rapidly or slowly.

Vibration Chambers

Vibration testing is completed using mechanical or electrodynamic shaking, which is usually done as part of climatic testing. The shaking can be vertical, horizontal, or along three different axes.

During the development of a new product, vibration testing is normally included in highly accelerated life tests (HALT) and highly accelerated stress screen (HASS) testing to determine the viability of a new product under the most stressful conditions. It is very common for vibration testing to be combined with environmental tests to determine a product’s ability to withstand normal operating parameters.

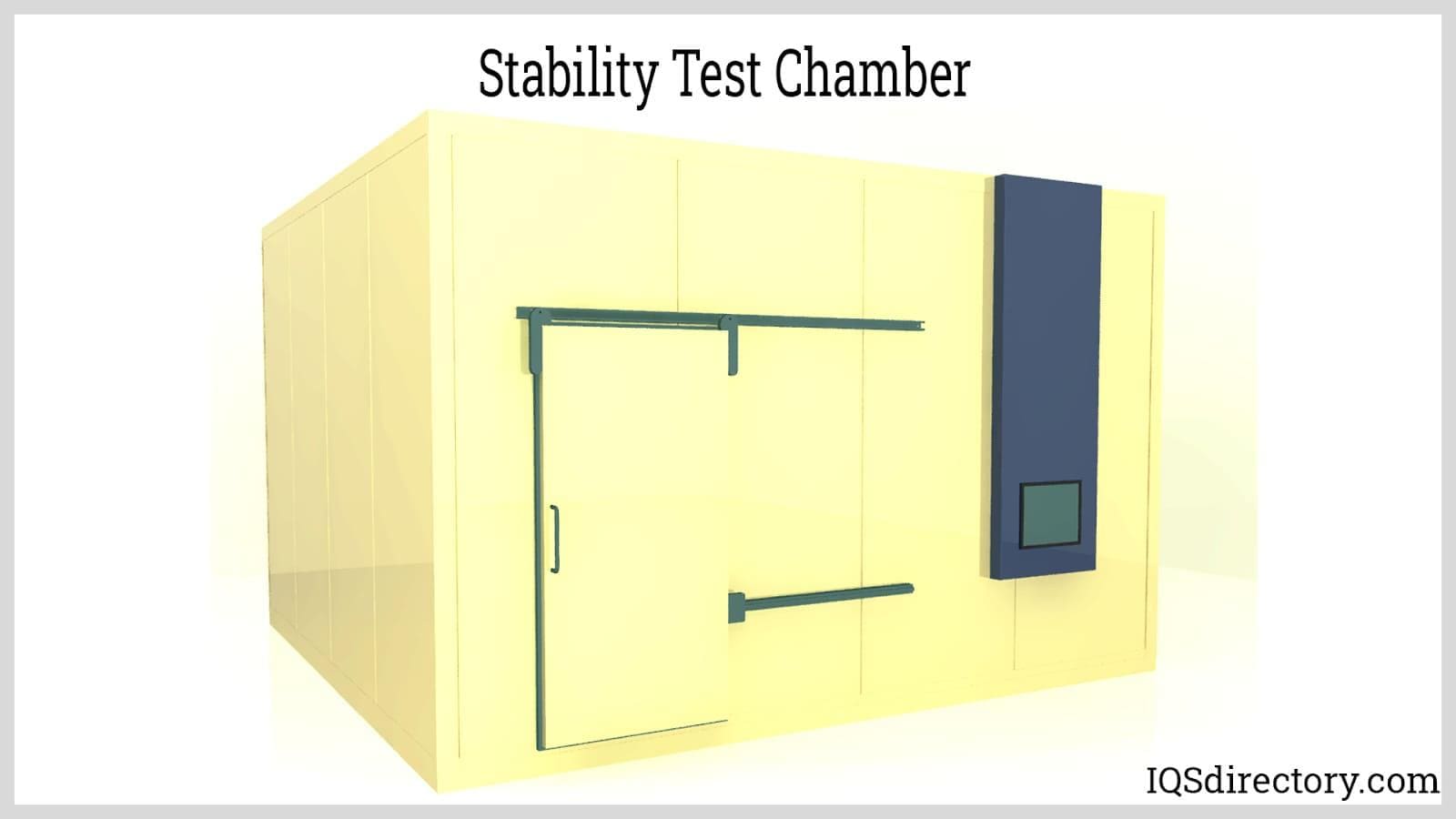

Stability Chambers

The purpose of a stability test chamber is to test a product’s reaction to temperature, humidity, and light over an extended period of time. A major concern for stability test chambers is the shelf life of a product to determine its lifespan and reliability when exposed to various environments during shipping and storage.

The International Conference on Harmonization (ICH) has divided the world into five climate zones. When the stability of a product is being tested, the parameters are determined by the zone where it will be used and shipped. These guidelines decide the settings on a stability chamber.

Salt Spray Chambers

A salt spray chamber produces a highly corrosive environment that tests the effects of long term exposure to salt saturated substances. The temperature in a salt spray chamber must be consistent to maintain the salt spray concentration. For the greatest consistency, salt spray chambers operate at 35° C.

Salt spray testing is designed to determine the stability of coatings and finishes when placed in corrosive conditions.

Thermal Shock Chambers

One of the concerns for many products is their ability to withstand sudden changes in temperature and atmospheres. When an engineer is designing a product, they have somewhat of a vision of the type of conditions the product is designed to encounter. To get a clearer picture of a product’s capabilities, it is essential to create the probable conditions it may encounter.

To achieve that goal and to gain a greater understanding of proposed products, manufacturers give their products thermal shock testing. This form of testing is the most severe and grueling of the different types of tests. The test consists of putting a specimen through a variety of environmental changes in rapid succession with temperature variants of 30° C every minute or more. This type of testing is designed for applications that will endure rugged duty.

Vacuum Chambers

A vacuum chamber creates a low pressure environment by removing air and other gases from an enclosed space. The purpose of this testing is to examine how a product or device performs in a vacuum. This type of testing is a requirement for products used by the aerospace and defense industries.

There are a wide variety of vacuum chamber sizes from ones that are the size of a room to others that can set on a counter. Instruments, gauges, and components that are designed for use on aircraft and space vehicles are required to be tested in a vacuum chamber.

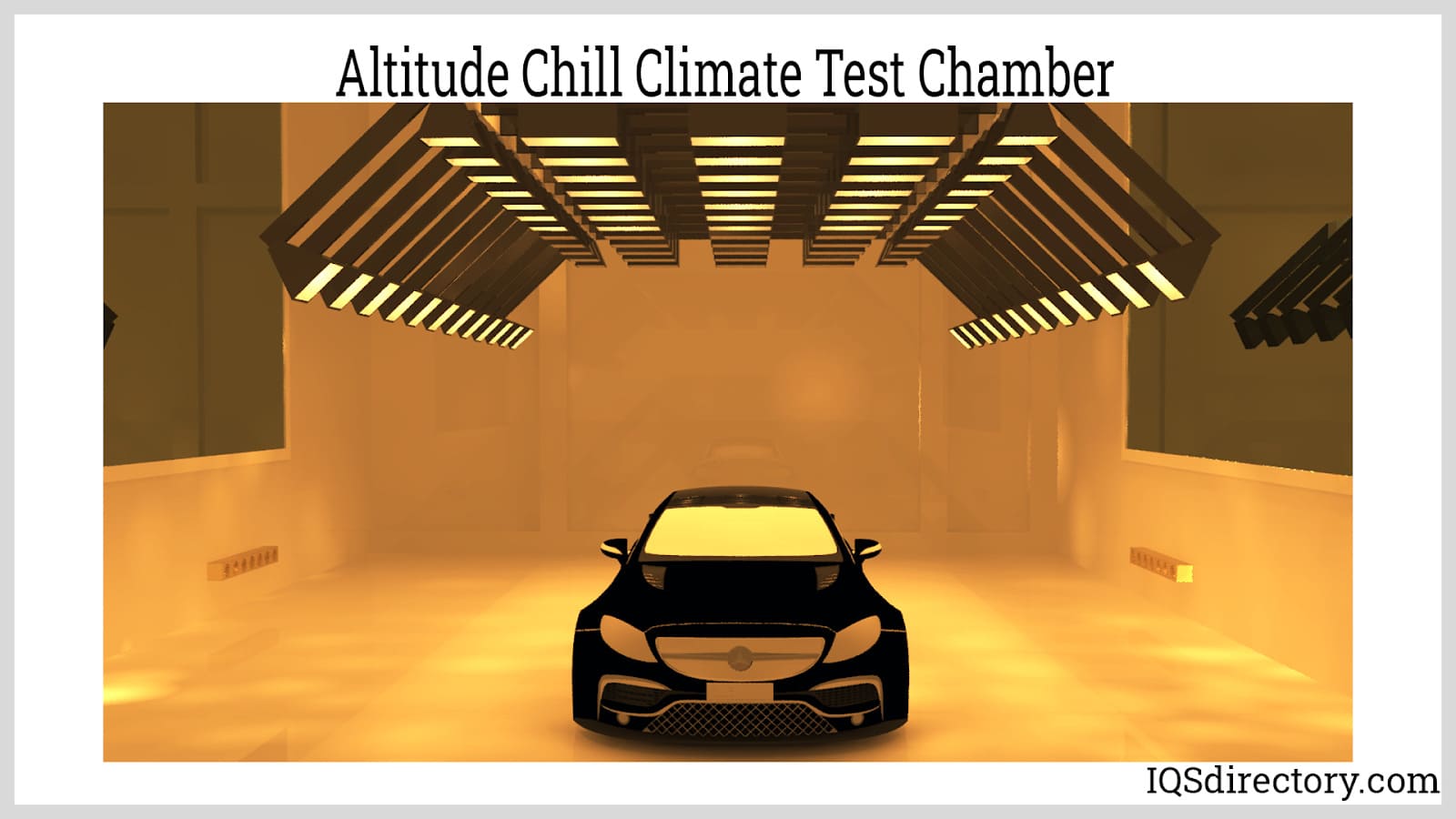

Altitude Chambers

The purpose of an altitude test chamber is to test the resiliency of a sample in low pressure at high altitudes. Altitude chambers are able to simulate conditions up to 30,000 m. Those conditions are combined with decompression and explosive testing.

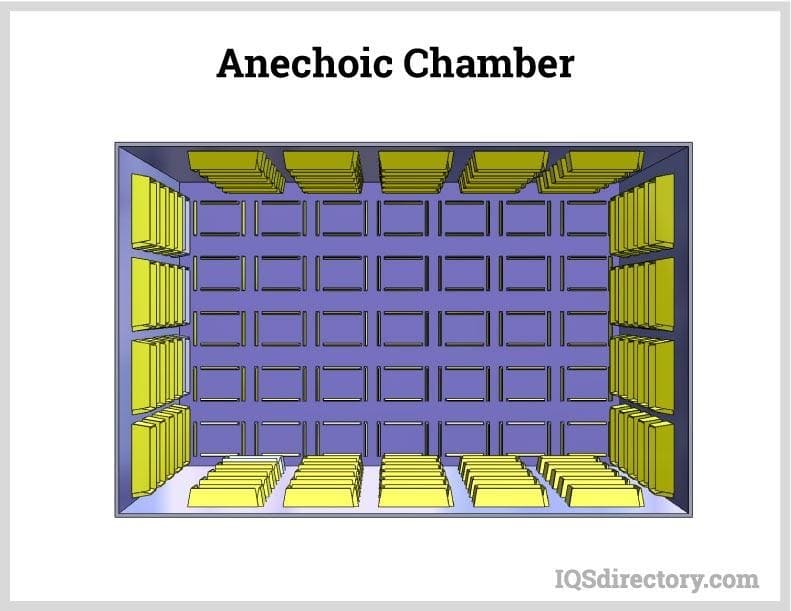

Anechoic Chambers

The word anechoic refers to the elimination of echoes. This type of chamber is the size of a room that is lined with materials designed to absorb sound and electromagnetic waves. Aside from containing waves in the chamber, anechoic chambers are designed to block out sounds in the area around the chamber.

The purpose of blocking out sound is to prevent extraneous noises from tainting test results. The purpose of anechoic testing is to determine how much noise a product produces. The types of products tested include cars, microwaves, buses, airplanes and computers.

Chapter Three – Uses for Environmental Chambers

Prior to the introduction of the first test chamber in the mid-20th Century, the way to determine if a product was sturdy enough and how long it would last was conducted by surveys, experimental groups, and exposing products to local climatic conditions. Those methods were time consuming and delayed presenting products to the public. In some cases, no testing was done, and products were put on the market, which led to a great deal of backlash.

Since the invention of environmental chambers, producers and manufacturers have been able to perfect and improve the quality of products as well as offer products with better performance and endurance.

Uses for Environmental Chambers

The purpose of an environmental chamber is to replicate the types of conditions that a product will confront when it is being used. Engineers, during the planning phase, attempt to predict the endurance and stability of their designs. Environmental chambers allow them to take their predictions and produce a facsimile of the conditions such that they can make adjustments and changes.

Temperature Variations or Thermal Testing

Temperature is the number one cause of product failure, which is the reason that most manufacturers test for its impact on their products. The data from a temperature test provides information regarding how much thermal endurance a product can withstand.

Humidity Testing

Humidity is the second factor regarding the deterioration of products. Moisture, in all forms, does significant damage to materials, substances, and products. This is especially true of humidity since it includes both moisture and temperature.

Air Pressure Testing

Air pressure can vary when a product is being transported, whether it is by air or truck. To determine the types of air pressure a product can withstand, it is subjected to several levels of air pressure in an environmental chamber. The consequent data gives producers a baseline for customers and an opportunity to make adjustments.

Thermal Shock Testing

Thermal shock testing is a form of temperature testing. During a product’s life span, it will be exposed to various temperature gradients. In normal temperature testing, the product is subjected to one level of temperature over an extended period. Thermal shock testing moves the product rapidly through a variety of temperatures in succession without hesitation. The purpose of the test to examine potential expansion and contraction problems as well as help determine at what point the product will fail. This form of testing is considered to be the most severe of the environmental tests.

Accelerated Aging Testing

The purpose of an accelerated aging test is to determine the specific lifespan of a product. An accelerated aging test subjects the product to stress that is designed to mimic the aging process. Prior to the development of environmental chambers, the aging process was tested by putting a sample to use for extended periods. Test chambers are able to speed up the process and provide data and estimates regarding product’s lifespan.

Xenon-Arc Testing

Xenon-arc testing is a process of exposing a product to cycles of radiation to simulate the types of sunlight a product will experience during normal use. A xenon-arc light produces light by passing electrical waves through ionized xenon gas at high pressure. The result is a bright white light that closely resembles the light of the sun. Xenon-arc testing is included in accelerated aging testing.

UV Weathering Testing

UV weathering is another test performed to determine the effects of sunlight on a product. Long term exposure to solar radiation can cause a wide range of effects from causing clothing to fade, plastics to weaken, or cement to crack. The damage to products is caused by invisible rays called electromagnetic radiation, which are UV waves, the types of rays that are produced by the sun.

Salt Spray or Corrosion Testing

Salt spray or corrosion testing is designed to assess how corrosion will affect the performance of a product. The process of this test is to expose samples to a highly concentrated saline environment for a predetermined amount of time. The types of products tested include coatings, paints, and other products that will potentially be exposed to a corrosive environment.

Salt spray testing can also be part of the accelerated aging process when the timing of the application of the saline solution is rapidly advanced.

Altitude Testing

The purpose of altitude testing is to determine the effects of high pressure and vacuum conditions on a sample. In a normal environmental chamber, when conducting an altitude test, temperatures can range between -65° C to 150° C at altitudes of -200 ft to over 100,000 ft. Altitude testing is normally done for products that will be exposed to air transport or space programs.

Chapter Four – Industries That Use Environmental Chambers

Environmental test chambers have become an essential part of industry. Manufacturers require accurate data regarding the reliability of their products. The ability of environmental chambers to produce accurate and simulated environments instantly and efficiently has proven to be a benefit for the development and testing of new products and services.

Every item that is used commercially, industrially, or in the home will be exposed to a variety of unique and unusual conditions. Each of these factors, such as temperature, vibrations, and humidity, can shorten the lifespan of the product or prevent it from performing up to expectations. It is for these reasons that manufacturers are relying heavily on the data provided by environmental chambers.

Industrial Use of Environmental Test Chambers

Automotive

The automotive industry relies on test chambers in several ways. Small environmental chambers are used to test small parts prior to their being inserted into an assembly. Larger parts, such as assemblies and mechanisms, are tested in larger environmental chambers capable of being loaded with more parts. As a final test, the completely assembled car is tested to determine how the various components interact.

Environmental test chambers for the auto industry have led to an improvement in the quality and lifespan of cars.

Electronics

Electronic devices are highly susceptible to failure due to environmental factors especially moisture, humidity, and temperature variations. Environmental test chambers are used to test the stability of electronic components for the conditions that they could encounter during their use. The list of components that are tested include ICs, circuit boards, semiconductors, transducers, surge protectors, touch panels, switches, and various assemblies.

Pharmaceutical

Environmental test chambers are widely used in the pharmaceutical industry to simulate the many temperature variations and types of humidity products will encounter. Tests in this industry go beyond the testing of products and include testing the endurance of packaging materials, which are critical to the preservation of the effectiveness of a drug.

An essential part of pharmaceutical testing is being in compliance with the many regulations, standards, and legal requirements placed on the industry. Environmental chambers have helped in the development of products to determine their lifespan, shelf life, and conditions that will cause them to deteriorate.

Defense

The military has a list of standards with specific detailed requirements regarding the manufacture of equipment for their use. The specifications are listed under United States Military Standards with the purpose of ensuring perfect performance of every product.

The main concern for the testing of military equipment is that they be able to endure the harsh, hazardous, and demanding conditions where they will be used. The key factor in the testing is that products will be reliable for the safety of military personnel.

Medical

As with pharmaceuticals, the medical industry has a set of standards and requirements regarding the quality of products used for performing medical procedures and testing. Aside from the normal specifications regarding quality, performance, and lifespan, the medical industry has restrictions for sterility, tensile strength, and reliability especially for life saving equipment, which must be strictly adhered to.

The Food and Drug Administration has validation requirements regarding the monitoring and process control for the manufacture of medical devices.

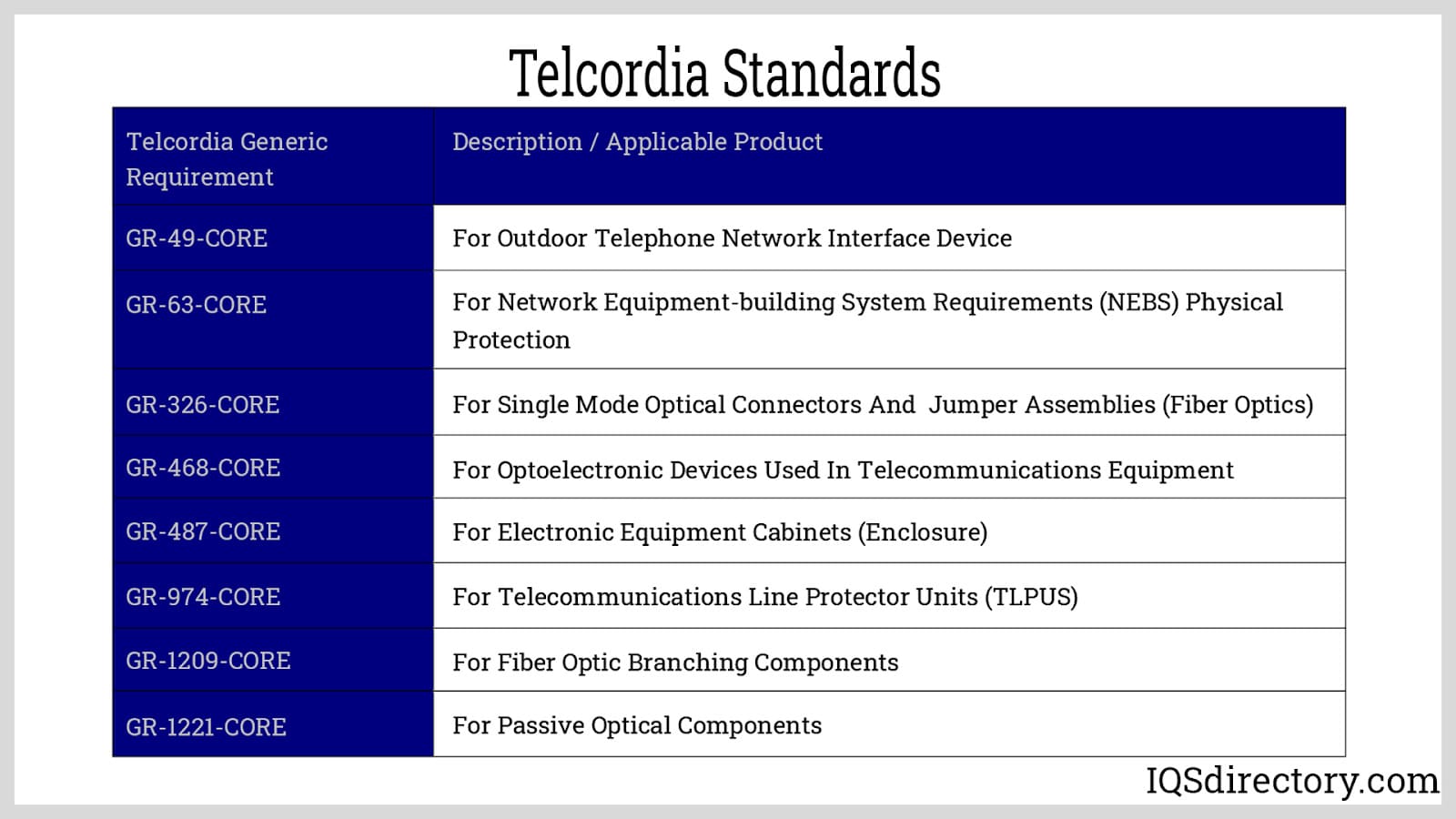

Telecommunications

The standards for the telecommunications industry were established by the American telecommunications research and development company Telcordia. The specifications outlined by Telcordia are followed by telecommunications‘ producers in determining the exact standards for all telecommunications devices.

Telcordia standards offer specific testing guidelines in regard to altitude, temperature, humidity, and other testing factors. The data accumulated by Telcordia offers predictions regarding the reliability of a product and gives specific calculations to determine potential effectiveness.

Solar Energy

The main focus of environmental testing for the solar energy industry is the testing of the resilience of solar panels and photovoltaic modules since they are constantly exposed to the environment. The types of testing include temperature cycling, damp heat, and humidity. The requirements for solar energy equipment testing have been established by the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and American Society for Testing and Materials (ASTM).

Aerospace

The aerospace and aviation industries use environmental chambers to test atmospheric conditions to ensure that they conform to the specifications of the Society of Automotive Engineers (SAE). The concerns for the aerospace and aviation industries are mainly safety, reliability, and efficiency. To determine the viability of a product, it is tested in an environmental chamber for thermal shock as well as the simulation of a variety of atmospheric conditions.

Chapter Five – Types of Environmental Chambers

There are environmental chambers that are designed to fit any type of condition, location, situation, and environment. They come in sizes to fit on a counter to ones that are the size of a building. The determining factors regarding the purchase of an environmental chamber is dependent on the product to be tested and its footprint.

Large room or building sized environmental chambers are planned to the most minute detail to meet the needs of the client as well as the type of testing to be done. In most cases, larger environmental chambers are capable of completing several types of tests and create a wide array of climatic conditions.

Types of Environmental Chambers

Benchtop Environmental Chambers

Benchtop environmental chambers provide the same accurate and quality data that can be found in larger chambers but have a smaller footprint with flexibility and cost effectiveness. Though they have a smaller design they can be equipped with the same data gathering computational devices found in more expensive equipment. Benchtop environmental chambers are ideal for university labs, small product companies, and for testing small components and parts.

Reach-In Environmental Chambers

Reach-in environmental test chambers have approximately the same footprint as benchtop chambers but are on wheels and set on the floor. They are vertical, which makes them mobile to move to different locations. Depending on the preferred style, they can have an observation window as well as a wide variety of monitoring and control devices for data collection.

Reach-in chambers can be configured to do simple temperature testing or humidity testing as well as being designed to perform a group of tests.

Walk-In Environmental Chambers

Walk-in test chambers are a more advanced type of testing chamber and can be purchased as a pre-manufactured unit for instant installation or configured to fit specific requirements. They can be assembled using connected panels or welded panels with welded panel designs being the most common and reliable. There are many varieties of walk-in chambers that can be engineered for a single type of testing or be capable of completing a series of tests.

The types of accessories include access ports, heavy load floors, various thicknesses of walls, noiseless, various door sizes, small or large windows, and a wide variety of LCD control mechanisms.

Drive-In Environmental Chambers

After all the parts and assemblies of a vehicle are tested, to ensure stability, they are tested as part of the fully assembled vehicle in a drive-in test chamber. Environmental chambers allow manufacturers to test all of the possible weather, atmospheric, and environmental conditions a vehicle may encounter during its use.

Due to the amount of investment, drive-in environmental chambers are designed and produced in accordance with the demands of the customer with features that specifically meet their requirements. In most cases, drive-in test chambers are capable of performing the full range of environmental tests from high altitude testing to rain, humidity, corrosion, and extreme temperatures.

Highly Accelerated Life Test (HALT) Environmental Chambers

A HALT test chamber subjects a testing sample to high levels of stress using thermal dwells, rapid temperature progressions, vibrations, and a combination of each type of the tests. The purpose of the test is to push the sample to failure, which includes forcing it through tests that are beyond its normal conditions of use.

The data collected specifies the destruct limits to discover the samples weak links to assist in making adjustments and improvements. The accelerated rate of the testing makes failures of samples quickly available, which cannot be achieved by normal testing methods.

High Accelerated Stress Testing (HASS) Environmental Chambers

The HASS test is normally applied after the HALT test and is more rigorous and demanding than the HALT test. It includes thermal cycling with vibration testing to find the defects in a sample. This continues multiple times until faults in the product are found. The purpose is to push the sample to failure for engineers to make corrections.

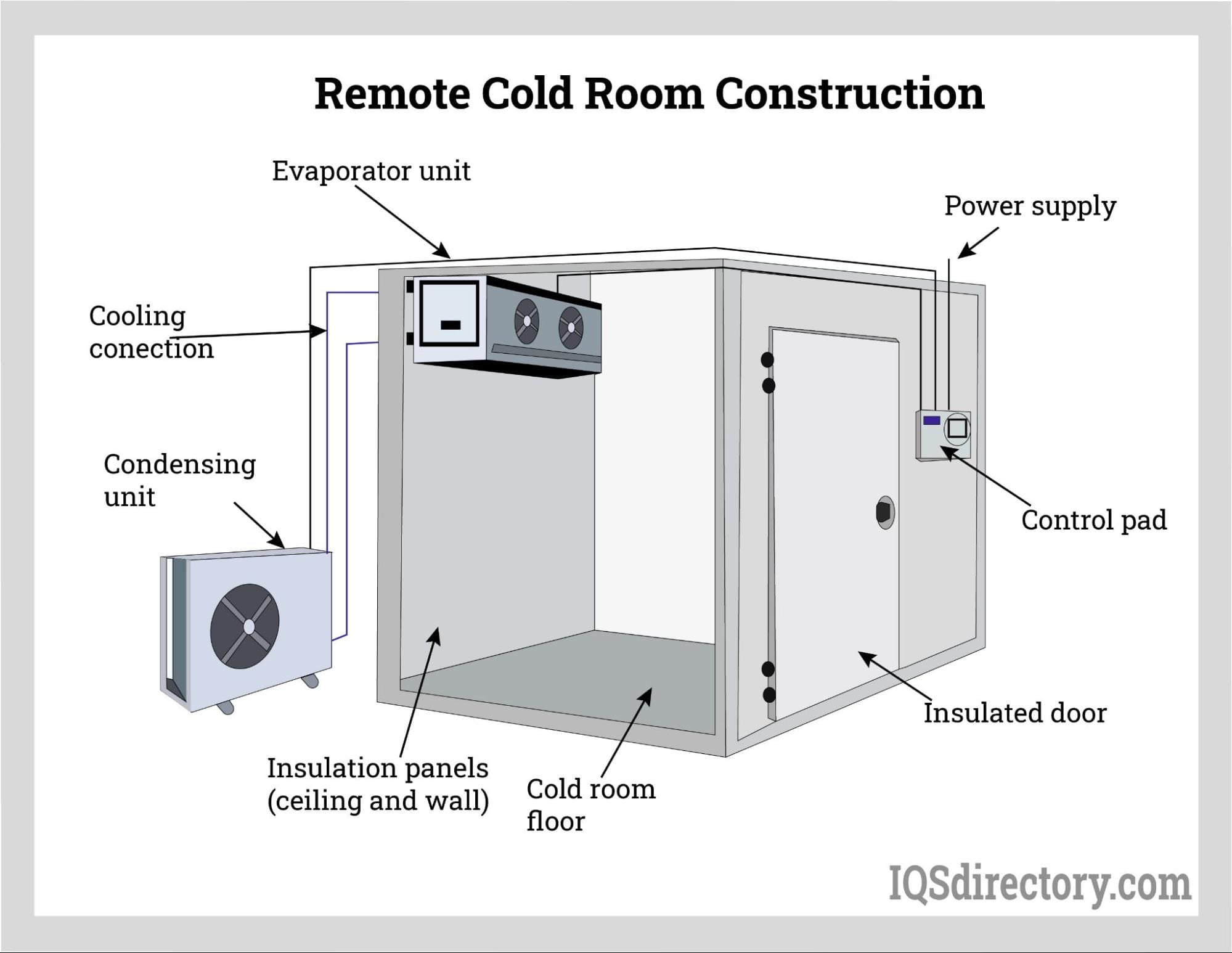

Environmental Chamber Assembly

Though all environmental chambers vary to fit the needs of the product to be tested, each type has basic features used for their assembly.

- Door – Test chamber doors are tightly sealed with gasket material that can vary from certain types of pliable plastics to various forms of rubber.

- Insulation – The critical feature of test chambers is their seal. This is achieved by having insulation material in the doors and walls.

- Walls – Test chambers have a steel exterior with a stainless steel interior to protect against contamination of the testing environment.

- Windows – Windows in test chambers are normally made of a clear polymer and are double paned.

- Controllers and Monitors – Controllers and monitors are the most critical part of an environmental chamber. They come in several varieties with ones that can be accessed remotely and have ports for USB drives. They help establish and control the pre-set conditions of the chamber.

Chapter Five – Environmental Chamber Regulations

Since environmental chambers are used in so many different industries, they have to meet the regulations, standards, requirements, and laws that apply to their industry. In the case of the medical and pharmaceutical industries, the agencies that oversee testing chamber protocols are related to both the government and regulatory groups.

The agencies that oversee and regulate the pharmaceutical industry include the U. S. Department of Health and Human Services Centers for Disease Control (CDC), the World Health Organization (WHO), the International Conference on Harmonisation (ICH), the Food and Drug Administration (FDA), and the Pharmaceutical Discussion Group (PDG). These agencies have requirements regarding the sterility of testing conditions, packaging, and the shelf life of drugs and medical instruments.

Regulations for the medical industry are similar to those for pharmaceuticals but also include the American Society for Testing and Materials (ASTM) and the International Electrotechnical Commission (IEC). Each of these groups provide guidelines for testing industrial, scientific, and medical equipment.

The requirements for testing of military equipment are laid out in the United States Military Standards (MIL-STD). These requirements give specific directions regarding the testing and development of equipment for the military that include the design of the testing as well as its limits. Each time a new piece of equipment is developed by the military, a new set of standards are created for its testing.

The standards for the auto industry include those published by the American Society for Testing Materials (ASTM), the Society for Automotive Engineers (SAE), and Underwriters Laboratories (UL). How detailed the regulations and requirements are relate to the organization and its goals. On the government side, the Department of Transportation (DOT) has safety standards regarding the testing of vehicles, which are further stipulated by each state‘s department of transportation.

The governing agencies for the electronics industry include the Institute of Electrical and Electronics Engineers (IEEE), the Joint Electron Device Council (JEDEC), and the Association Connecting Electronics (IPC). Each of these organizations specify the types, times, and limits of tests to be performed on electronics products.

The telecommunications industry has been guided by the Telcordia Standards, which have become the foundational values of the industry. In conjunction with Telcordia is the Telecommunications Industry Association (TIA), which is a sector of EIA.

The American National Standards Institute (ANSI) is a private organization whose members work together to develop standards for products, services, processes, and systems. Their main focus is to ensure that the performance of products is consistent across all industries and producers.

The organizations listed above are some of the primary groups that ensure that product testing is completed as an organized and planned process for the protection of the public and manufacturers. The types of groups can be specific to a country or be international depending on the product and its impact on the market.

Conclusion

- An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly

- The stipulations and requirements for testing are predetermined to offer the most accurate data concerning a product’s performance in the types of conditions it would confront during its use.

- Environmental chambers come in a wide variety of sizes and designs in order to meet the changing demands of industry.

- Since the invention of environmental chambers, producers and manufacturers have been able to perfect and improve the quality of products as well as offer products with better performance and endurance.

- Since environmental chambers are used in so many different industries, they have to meet the regulations, standards, requirements, and laws that apply to each industry.

Check out our Linear Actuators website

Check out our Clean Rooms website

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services