With more than 50 years of experience, Thermotron is a global leader in the design and manufacturing of environmental test chambers and vibration test systems. Used by many of the world’s top brands, our equipment tests products for the automotive, space, defense, electronic, renewable energy, and many other leading industries. Our robust, intuitive controllers run on a Windows platform...

Isotech, Inc. is a leading manufacturer and provider of environmental test chambers, thermal platforms, and related equipment. The company has been in operation since 1984 and is headquartered in Hatfield, PA, with additional facilities in California and Europe. Isotech's products are used for a variety of applications, including research and development, production testing, and quality...

More Environmental Testing Manufacturers

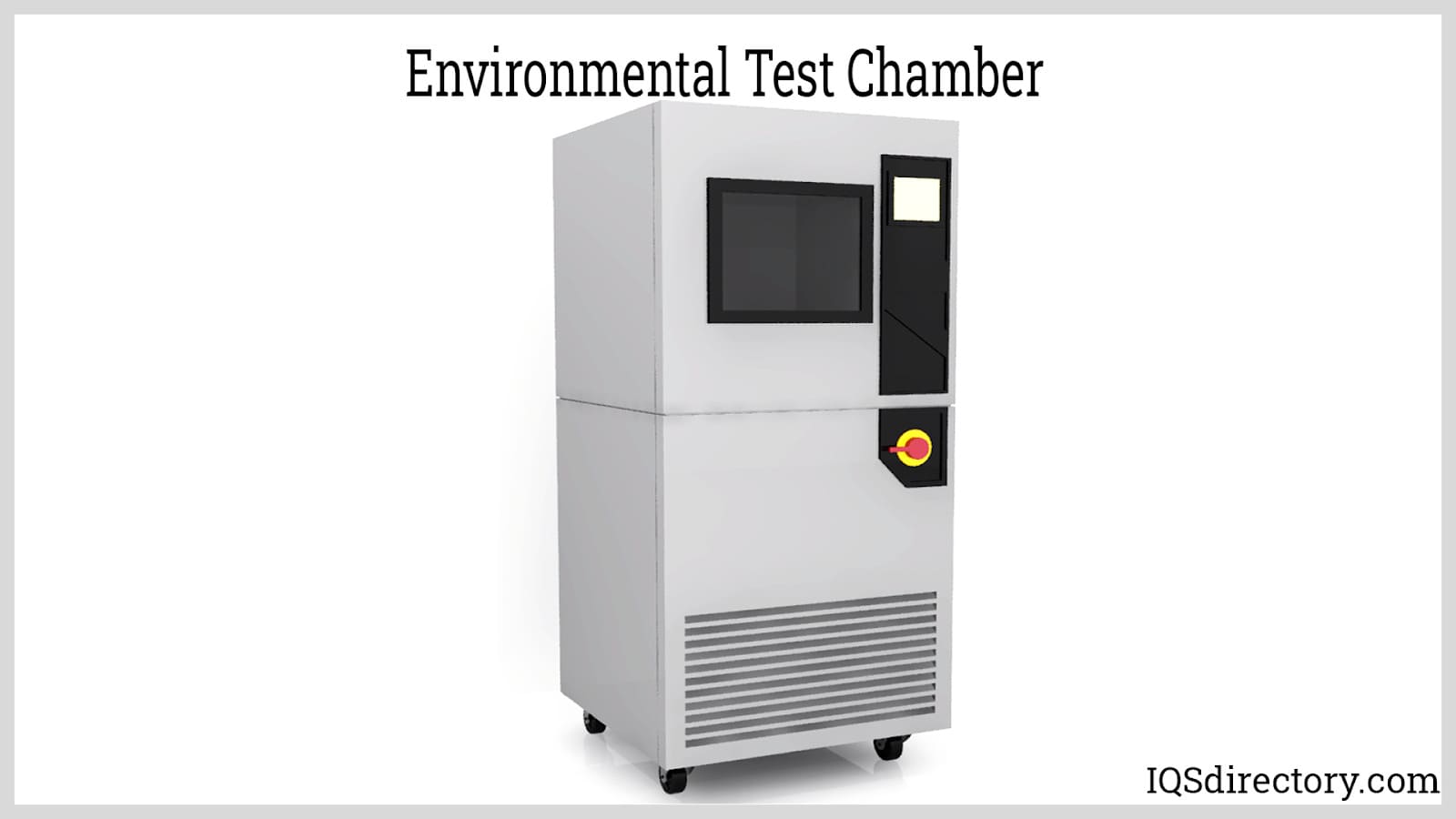

Environmental testing is the measurement of the performance of equipment under specified environmental conditions. Chambers are used to simulating a full range of temperature testing and humidity testing conditions. There are many types of chambers, including salt spray test chamber, high and low-temperature test chamber, constant temperature and humidity test chamber, ultraviolet aging test chamber, xenon lamp aging test chamber, ozone aging test chamber, and ovens. The main function of an environmental test chamber is to see how products handle operating in various environments.

Environmental chambers allow for control over various conditions. In order to be released a product must be able to operate in a wide variety of environments, both storage and operational. Testing allows designers to take environmental factors and standards into consideration. Environmental testing is important to understand the longevity of a product and to understand if they meet or exceed safety standards and requirements.

Environmental tests can test altitude, explosive atmosphere, fluid compatibility, fungus, ice/freezing, rapid and explosive decompression, salt fog, sand and dust, solar radiation exposure, temperature and humidity, wind, waterproofness and immersion, and life cycle testing.

How it works

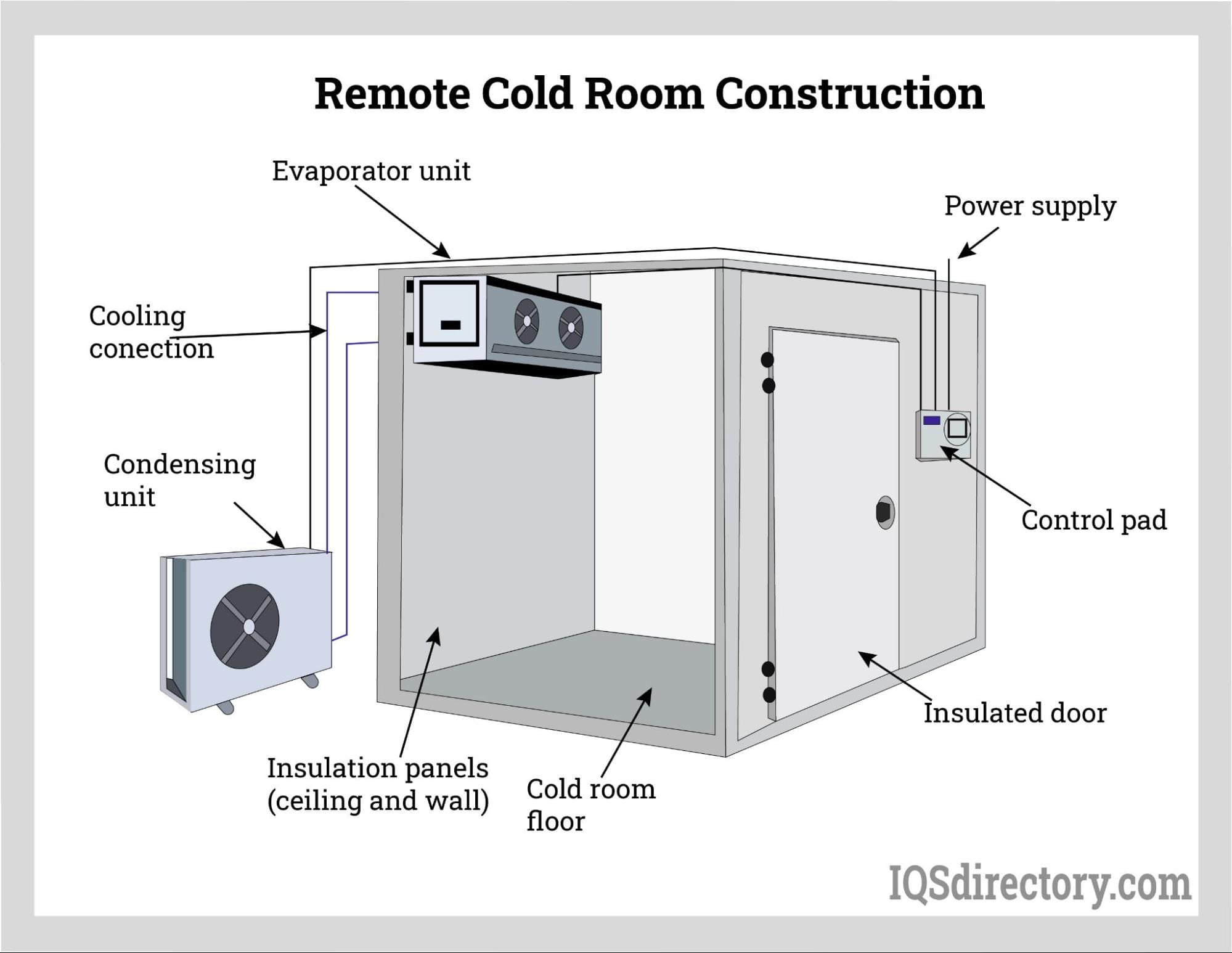

Humidity in the test chamber can be simulated by evaporation of water with a heat source or with ultrasound technology. Water vapor can be introduced using a steam generator. Refrigeration systems are used to cool the environment.

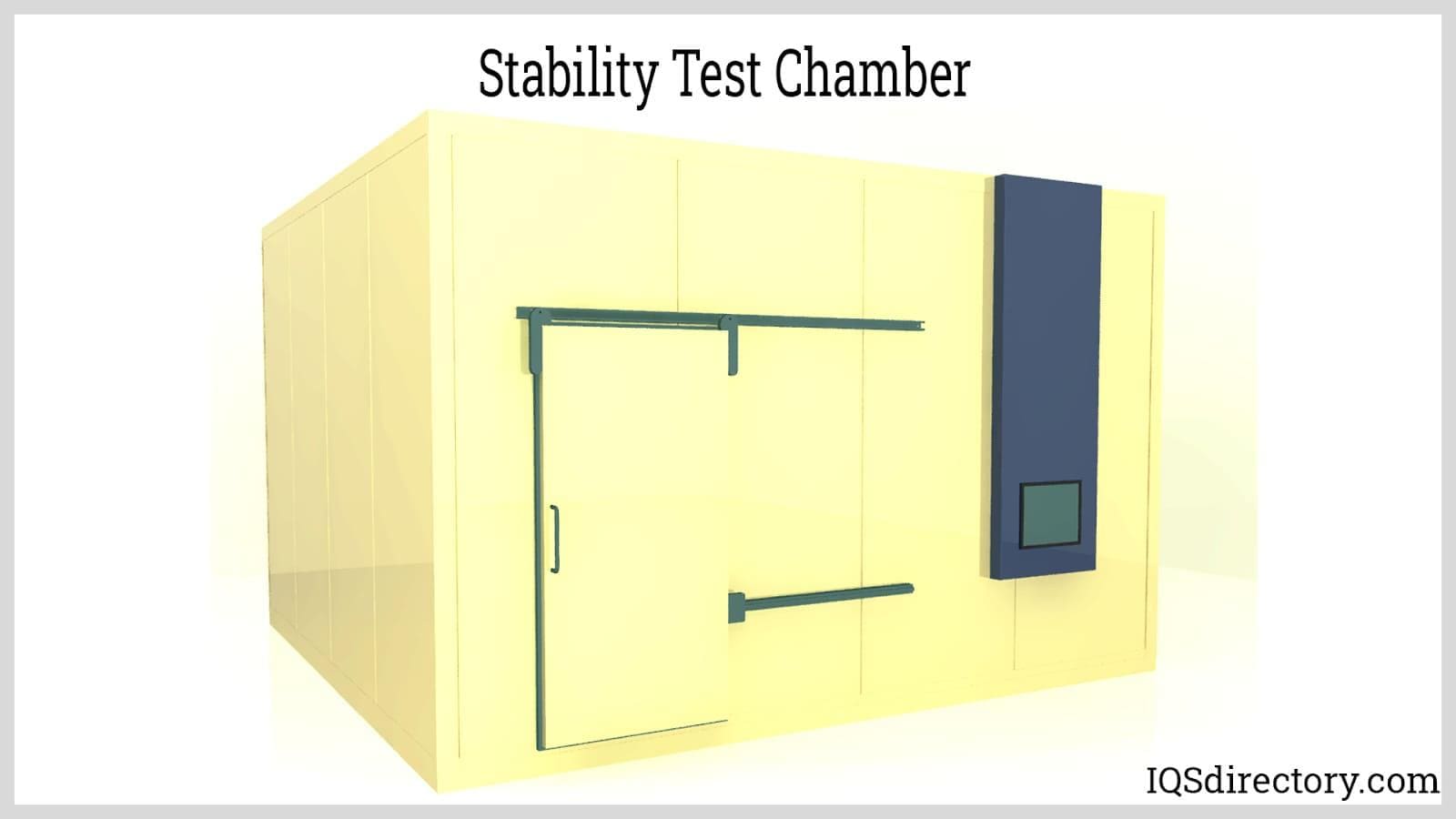

Test chambers vary in size and can be custom-built for unique needs. Chambers can fit on a counter or be designed as walk-in chambers the size of small rooms. Generally, test chambers have viewports or video feeds that allow for ease of monitoring. Some chambers allow for reach-in openings that allow for sample testing.

Standards

Test chambers must follow several organizational standards and guidance in construction, temperature control standards, and engineering tolerances. Including:

● Institute of Environmental Sciences and Technology

● Air Conditioning, Heating and Refrigeration Institute

● ASTM International

● Underwriters Laboratories

● NSF International

● FM Global

● Canadian Standards Association

● International Organization for Standardization

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services