Obviously, this kind of chamber is specifically used to test how certain products withstand and perform at a variety of different pressures. Read More…

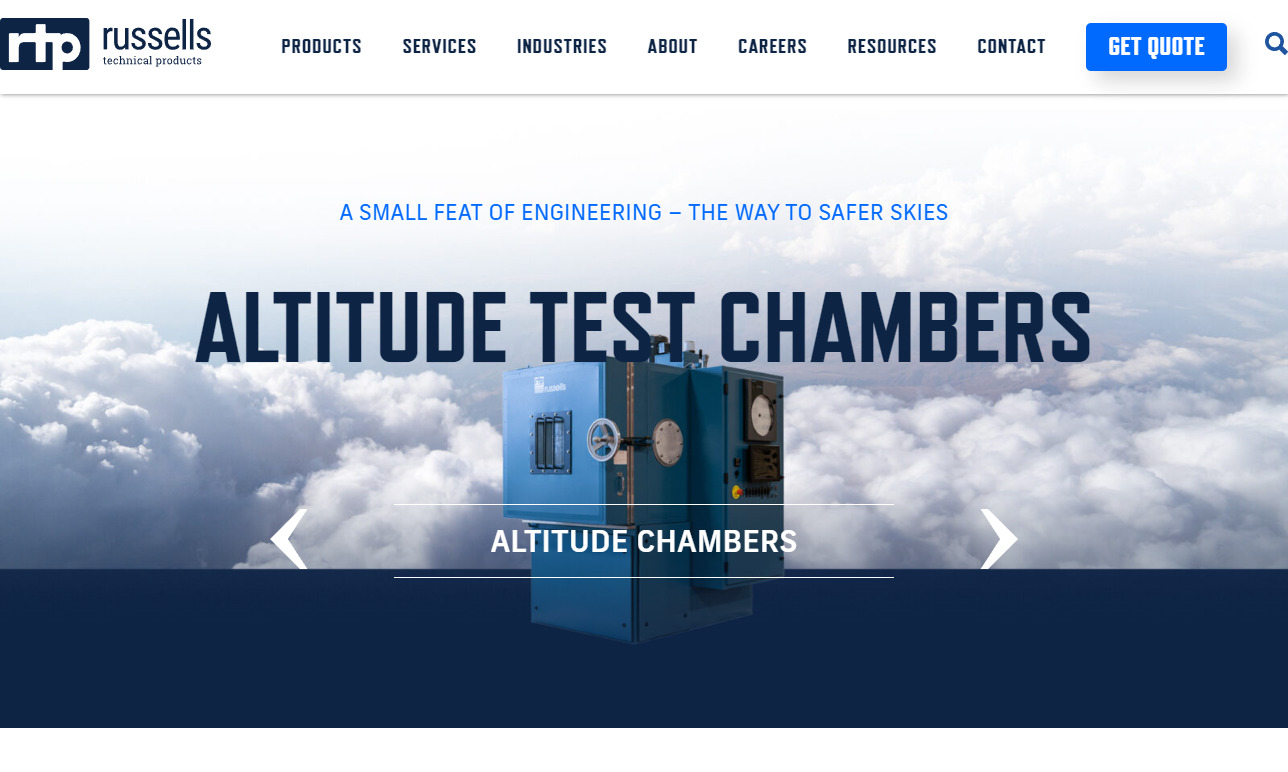

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Pressure Chamber Manufacturers

Typically, manufacturers use this kind of equipment to test the limits of their products or to determine if any modifications should be made to the product's design. Pressure chambers are a great way to ensure quality control in products, specifically dealing with products that will operate in a variety of different forms of pressure. Typically, these products will be tested under extremes in order to ensure that they will operate at normal levels which mean that a pressure chamber itself must be able to handle these extremes without losing any functionality.

In order to receive a product that will satisfy your expectations and needs, being able to communicate your needs to your pressure chamber manufacturer is vital to the success of the final product. Knowing what type of ranges you would like to test under and the size of the actual chamber will greatly change how the manufacturer will handle the actual manufacturing process.

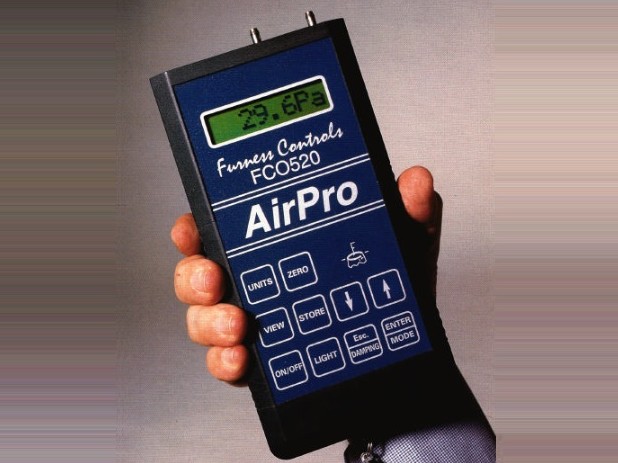

Typically, the pressure will be displayed through the use of pressure gauges and the operator will be able to adjust the pressure accordingly while monitoring these gauges. These chambers are typically constructed to withstand the forces associated with high and low pressures, but it is important to monitor the pressure to avoid any catastrophic events.

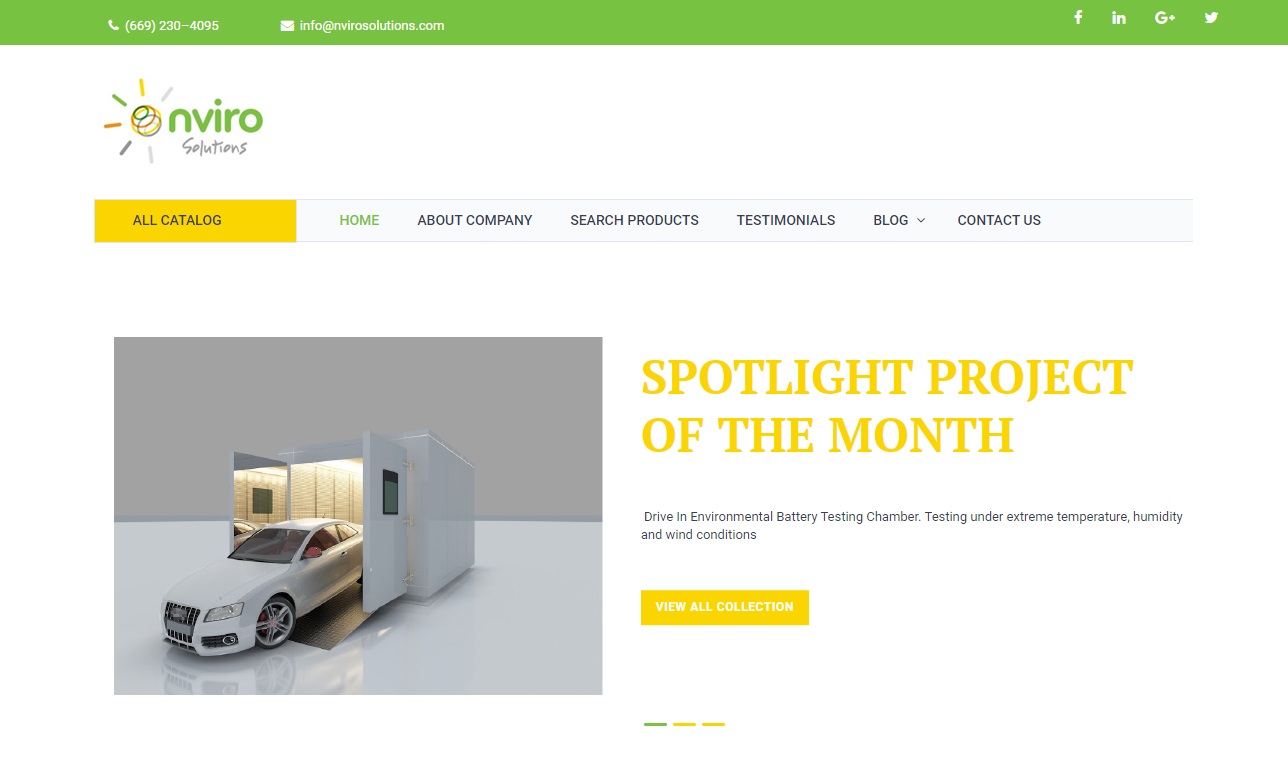

These chambers are used in a variety of industries and applications; the marine industry is one example. They can be used to test equipment for use at great ocean depths, where pressures become extreme, making these chambers a crucial component of the development product. Some of these chambers are able to simulate up to 60,000 psi of pressure all with proper control and decompression tools in place, and they can also reduce pressure to create vacuums.

So whatever your application may be, researching and contacting a knowledgeable pressure chamber manufacturer is the best step you can take to ensure that the product you receive is one that will satisfy the requirements of your application while keeping your workers and products safe. Whether you are looking for pressure chambers or other forms of environmental test chambers, knowing your needs and specifications will ensure a product that meets and exceeds your requirements.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services