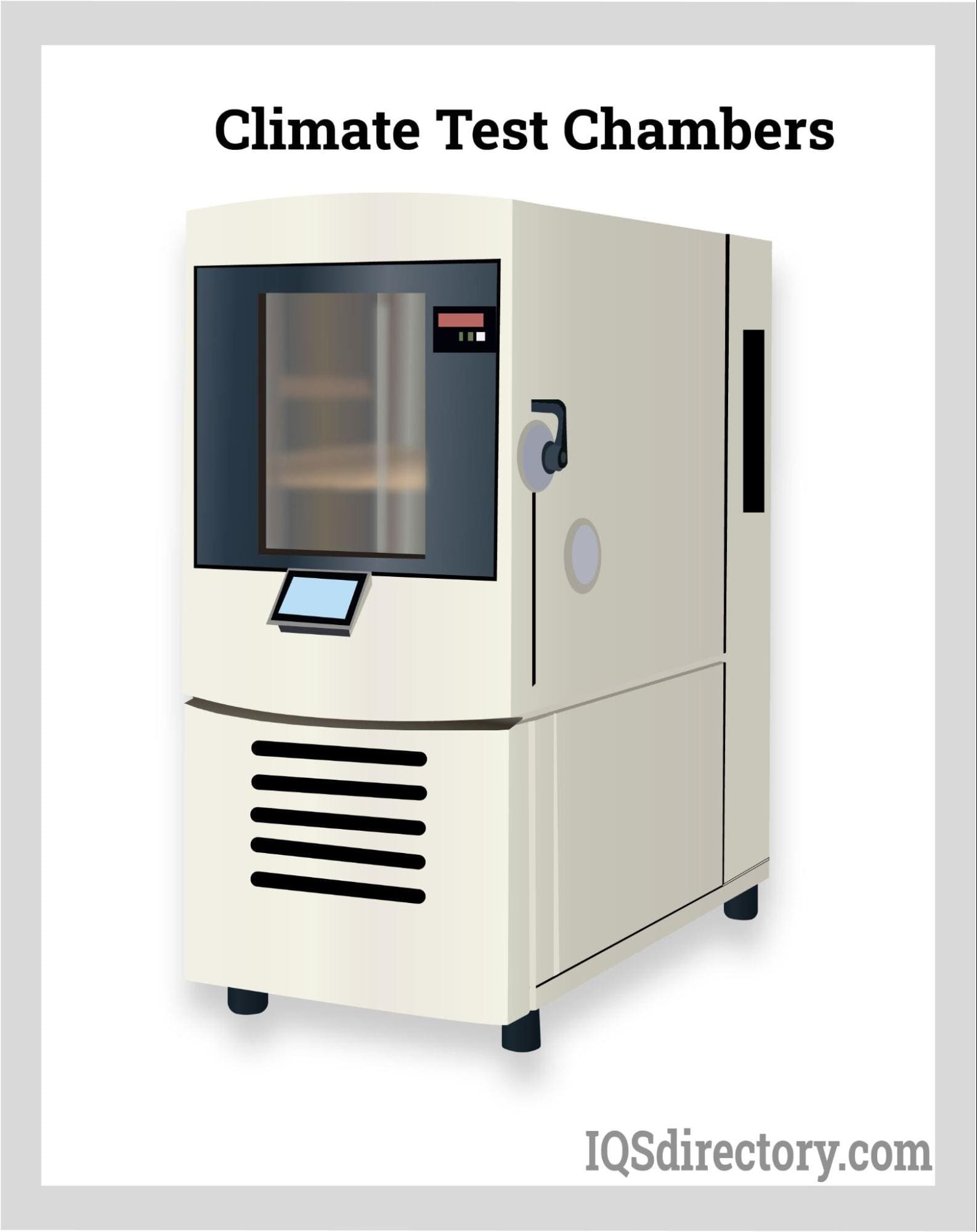

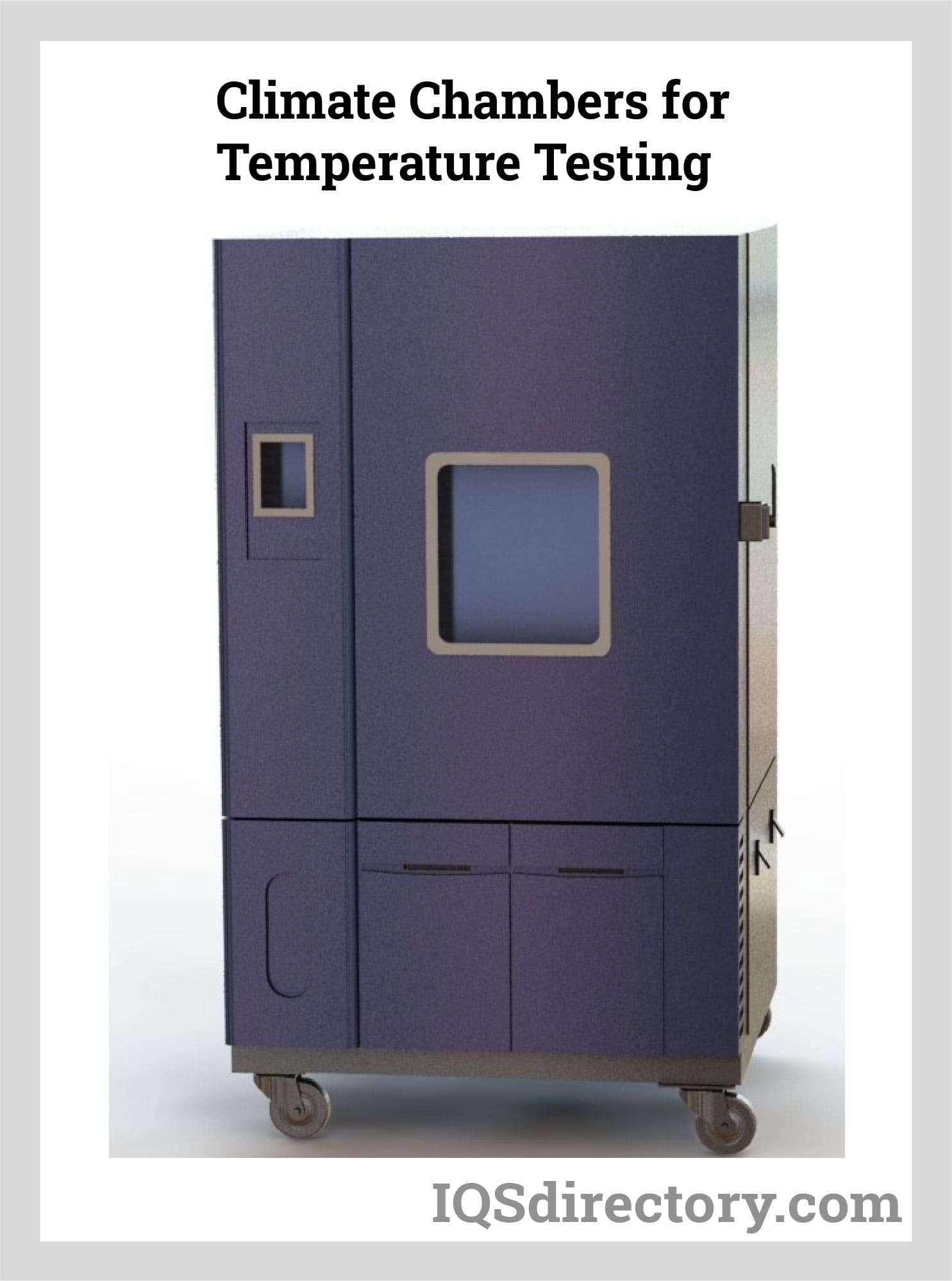

A climate chamber is a type of environmental testing chamber that consists of an enclosed space with a set of controlled climatic conditions. This chamber is ideal to use for testing the impacts of various climatic conditions on industrial goods, electronics, material, and other biological matter. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

From temperature chambers to salt spray chambers, Hastest Solutions is your source for sophisticated climate chambers. Over our long history of test chamber design and manufacturing, we have earned a reputation for providing innovative, reliable, and safe climate chamber solutions, and we are the manufacturer of choice for the semiconductor, automotive, aerospace, military, medical, and many...

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Climate Chamber Manufacturers

Product testing is necessary prior to shipping the products to assess their behavior in different environmental conditions. It is important to check the failure or success of a product to understand its durability. The tests usually performed in climate chambers are temperature simulation, effects of humidity, light forms, thermal shocks, long term stability, and many more to accumulate reliable data about the product.

Construction of Climate Chambers

All climate chambers are made of stainless steel regardless of their size. This material is used because of its tensile strength, durability, and impenetrability. There are two layers of climate chambers, the outer and inner layers.

The outer layer is made of heavy steel that is tightly welded, and the inner layer is made of similarly tight stainless steel. A layer of insulation between both layers protects the product from any kind of environmental stress that might change test results.

Design of Climate Chambers

Climate Systems

Climate systems are an essential part of these chambers and are designed to provide uniform air circulation within them. An important aspect of the climate system is the cooling compressor system that provides precise climatic control for testing purposes.

Climate Chamber Steam Humidifier

The steam humidifier is connected to the humidity sensor and helps in providing a water supply system for humidification and dehumidification within the chamber.

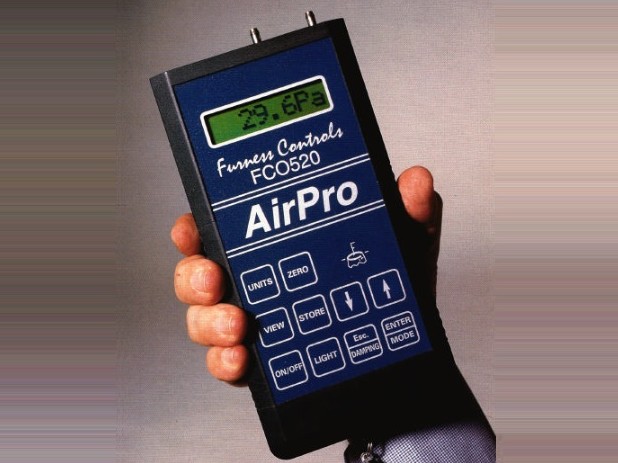

Chamber Regulation System

The chamber regulation system is controlled by a human touch to monitor the progress of the chamber. Other components of the system include the following:

Alarm Status

An alarm control list contains various types of alarms for high and low pressure, open door, power stops, etc.

Settings

The control panel has settings for various functions such as temperature controls, pressure controls, on and off compressor, etc.

Diagnostics

The chamber has a diagnostic system that gives an overview of every operation with light indication.

Service Indicator

The service screen monitors each of the components and gives data on when to provide service.

Types of Climate Chambers

Following are the types of climate chambers:

Benchtop Climate Chambers

Benchtop climate chambers are small and easy to install. Due to their small size, their footprint is small with dynamic performance. These chambers are reliable, efficient, mobile, and ideal for small labs with limited space.

Constant Climate Chambers

This climate chamber creates a stable environment by maintaining temperature, humidity, and lighting for a longer period of time. Constant climate chambers are designed to test the product’s behavior in harsh conditions.

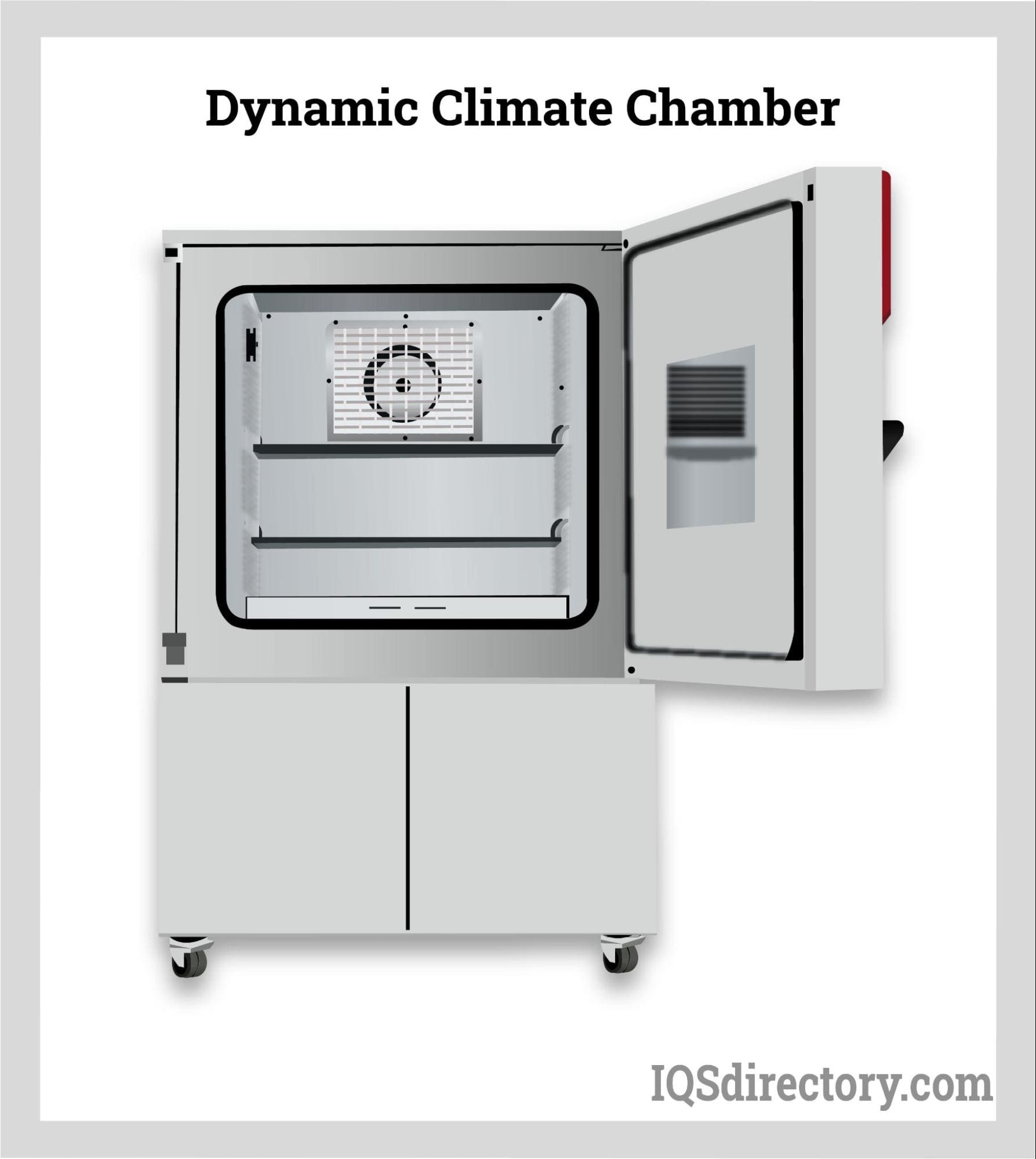

Dynamic Climate Chambers

Dynamic climate chambers are designed to check the impact of rapid changes in temperature and humidity. The purpose of this chamber is to create thermal shock by passing components through multiple climate changes quickly. This testing chamber is used for automotive, metallurgical, and aerospace industries.

Reach-in Climate Chambers

Reach-in climate chambers are bigger than benchtop chambers, with sizes varying from 4 to 70 cubic feet. These are easy to install, have a low footprint and larger capacity, and perform tests with great accuracy. Common tests performed in these chambers are plant growth testing, tissue culture testing, and germination.

Stability Climate Chambers

Stability climate chambers are a type of constant climate chamber that provide a stable environment for testing factors related to storage. This test chamber is an excellent method for examining building materials.

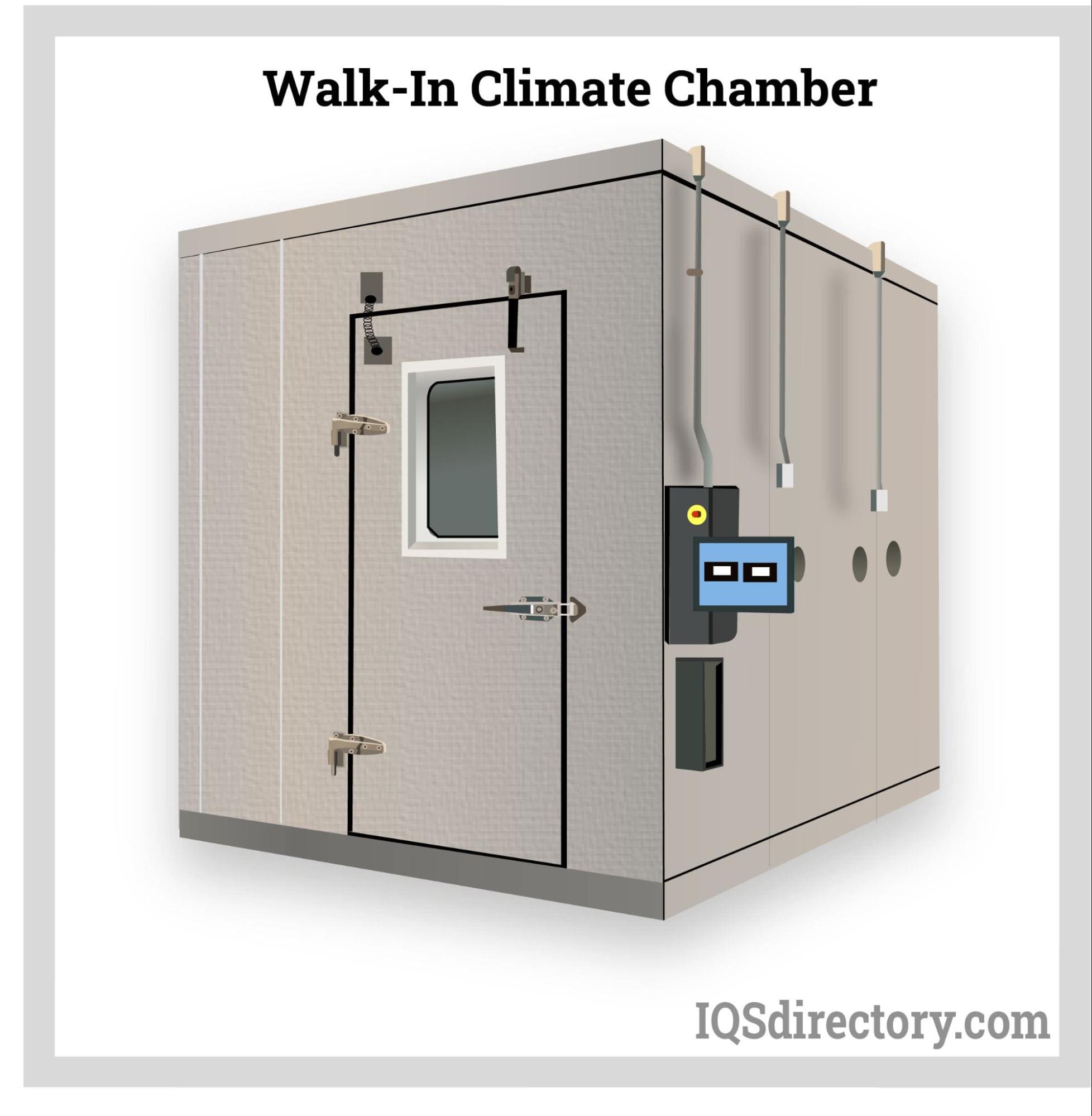

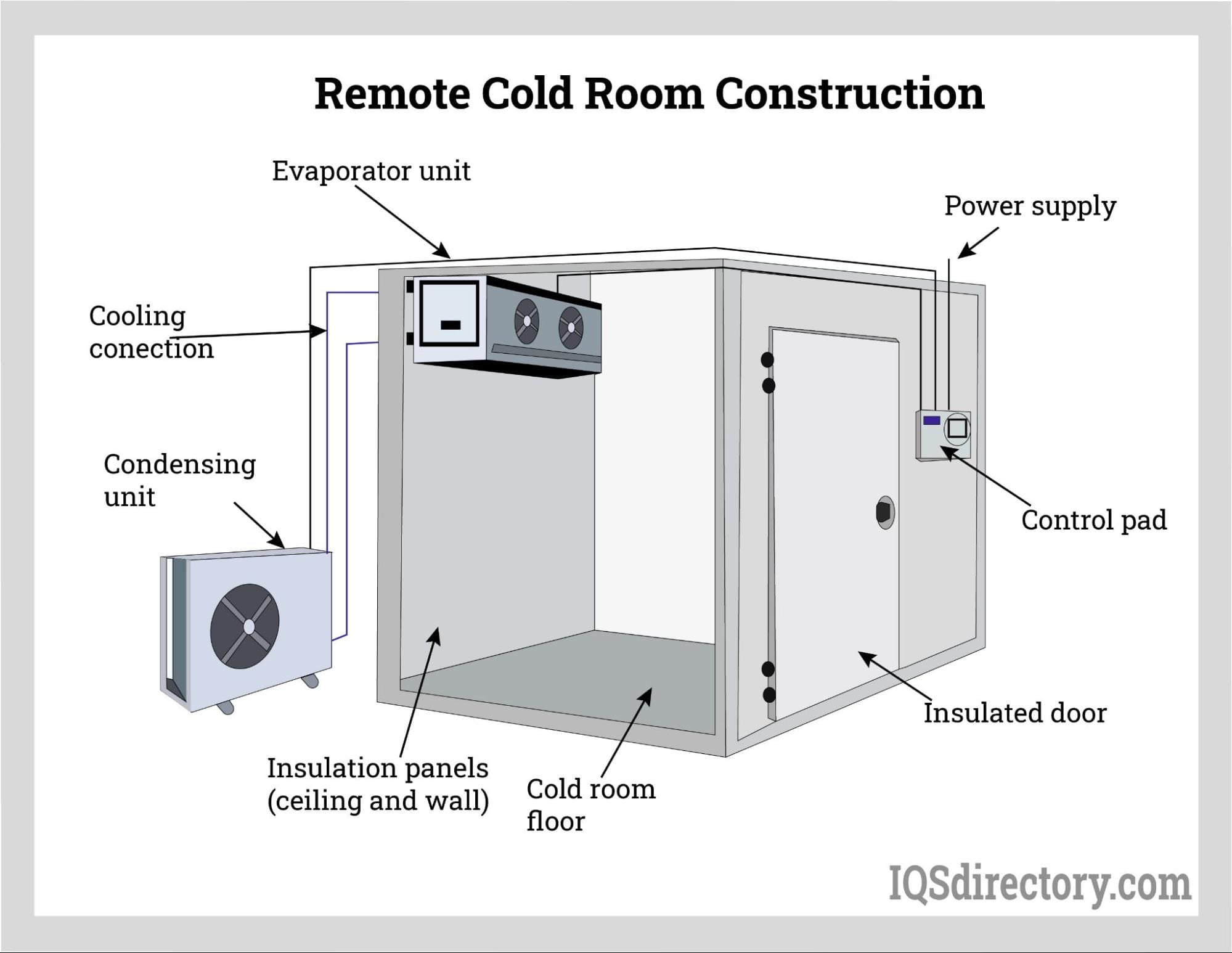

Walk-in Climate Chambers

Walk-in climate chambers are the largest climate testing chambers, meaning they can test large specimens with large footprints. These chambers can be customized according to the type of specimen to be tested. They have an outside banding that prevents leaks and moisture from entering into the chamber.

Applications of Climate Chambers

- Climate chambers are used in the aerospace industry for testing equipment such as avionic hardware and devices.

- These chambers are also used in the automotive industry for testing vehicles to ensure the safety of consumers.

- The pharmaceutical industry uses these chambers to test medications before storage and use.

- Cosmetics are tested before launch in these chambers.

- The food and beverage industry uses climate chambers to determine the shelf life and expiration dates of products.

- Different packaging industries use these test chambers to find out which packaging fits best for storing and shipping certain products.

Choosing the Right Climate Chamber Manufacturer

For the most productive outcome when purchasing a climate chamber from a climate chamber manufacturer, it is important to compare several companies using our directory of climate chamber manufacturers. Each climate chamber company has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each climate chamber business website using our patented website previewer to learn more about what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services